- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-11 Origin: Site

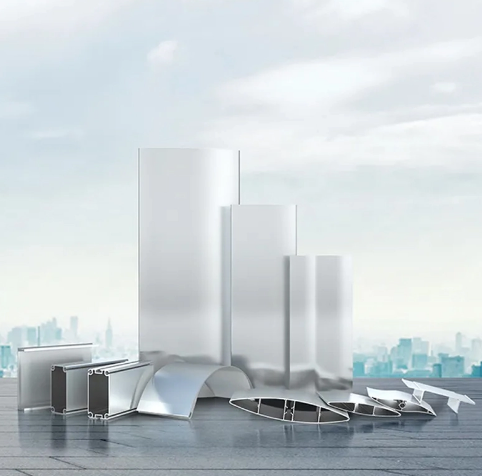

Aluminium profiles don’t have one “standard size.” Most are custom cross‑sections, but common ranges are 10–200 mm wide, 1.0–5.0 mm wall thickness, and standard lengths around 6 m (cut‑to‑size available). T‑slot series often come in 20×20, 30×30, 40×40, 45×45, 60×60, while large presses enable sections up to roughly 480 mm.

Standard stock length: ~6 m; cut lengths available

Common envelopes: 10–200 mm; larger on request

Wall thickness: ~1.0–5.0 mm typical; application‑driven

T‑slot families: 20×20, 30×30, 40×40, 45×45, 60×60; slot 6/8/10 mm

Window/door frame depths: ~50–150 mm; glazing dependent

Curtain wall mullions: depth sized by wind load; often 50–250+ mm

Max section capability: ~480 mm; single length up to ~40 m

| Use case | Typical size envelope | Wall thickness | Standard length | Notes |

|---|---|---|---|---|

| T‑slot frames | 20×20 / 30×30 / 40×40 / 45×45 / 60×60 | ~1.5–3.0 mm | ~6 m | Slot 6/8/10 mm families |

| Windows/doors | Frame depth ~50–150 mm | ~1.2–2.5 mm | ~6 m | Thermal‑break options |

| Curtain walls | Mullion depth ~50–250+ mm | ~2.0–5.0 mm | ~6 m | PVDF finishes common |

| Standard channels/tubes | 10–200 mm | ~1.0–4.0 mm | ~6 m | Broad stock availability |

If you searched “What size are aluminium profiles?”, you likely need fast, credible size ranges to kickstart a drawing, verify a supplier’s quote, or compare systems before committing. This guide gives a practical, answer‑first overview of extruded aluminum sizes: common cross‑section envelopes, wall thickness bands, standard stock lengths, T‑slot series mapping, window/door frame depths, and curtain wall mullion sizing. It then explains how sizes shift by use case—Construction Aluminium Profiles, Industrial Aluminium Profiles, Aluminium Standard Profiles, and Aluminium Green Building—so you can choose confidently and avoid overbuilding. We’ve also included an aluminum extrusion sizes table and scenario comparisons, plus tips for wall thickness and finish choices that keep weight down and stiffness up.

Aluminium Profile and aluminum profile refer to the same thing: a long, extruded shape with a fixed cross‑section. Size is defined by four simple elements:

Cross‑section envelope (width × height). This is the maximum outside dimensions of the shape. Typical “everyday” envelopes run from 10 mm small trims through 200 mm structural pieces; large presses can make much larger, approaching about 480 mm across.

Wall thickness. Most general‑purpose designs use around 1.0–5.0 mm walls. Stiffer beams, high‑load mullions, or heavy T‑slot frames may push thicker in key areas.

Standard length. Industry‑standard stock length is near 6 m because it ships and handles well. Cut‑to‑size is routine; single pieces can be produced much longer if needed.

Families and systems. In factories, T‑slot aluminum profile sizes 2020 3030 4040 4545 6060 are common. In buildings, “frame depth” replaces series naming and depends on glass thickness, wind load, and thermal targets.

If you need a snapshot of extruded aluminum sizes for a quick feasibility check, the ranges above will steer you right. When in doubt, ask your supplier to share a simple aluminium profile wall thickness chart and an aluminum extrusion sizes table matched to your loads and spans.

The typical standard length for an Aluminium Profile is around 6 m. That’s long enough to optimize cutting plans and short enough for common transport. For special projects, single‑piece lengths can extend dramatically with the right handling—think extra‑long façade blades or walkway rails—but most teams prefer 6 m stock and specify cut‑to‑size for installation. Cut lengths speed up fit‑out, reduce site waste, and shrink packaging needs. If elevators, stairwells, or tight rooms constrain your project, specify maximum lengths in your RFQ so the cutting plan aligns with logistics on day one.

Tolerance matters more than most people think. For a clean install, set tighter tolerances only where parts mate (like sash/frame interfaces or T‑slot end plates) and keep general faces at standard. This avoids unnecessary scrap and lead‑time extensions while still delivering the precision you need.

Windows and doors

Frame depth: roughly 50–150 mm depending on glass build (single, double, triple), hardware, and thermal break width.

Sash sections: similar depth to frames, often with slimmer sightlines.

Glazing beads and accessories: small trims typically in the 10–30 mm range.

Wall thickness: about 1.2–2.5 mm for residential/light commercial frames; heavier where spans or loads demand it.

Standard length: ~6 m stick lengths; cut‑to‑size and machining (mitering, drainage, hardware pockets) are routine.

Curtain walls

Mullion depth: often 50–250+ mm, set by wind load and allowable deflection.

Transom depth: similar to mullions, sometimes lighter where spans are shorter.

Pressure plates and snap‑covers: thin but stable; widths match glass sightlines.

Wall thickness: about 2.0–5.0 mm depending on spans, loads, and alloy/temper.

Systems thinking: deeper mullions carry larger glass with less steel; PVDF finishing is common for high‑UV and coastal sites.

Louvers, ceilings, and trims

Louvers: blade widths from 50–200+ mm; thickness tuned to span and wind.

Ceiling tees and cover edges: 10–50 mm trims; light walls for ease of install.

If you’re building an aluminium window profile size guide for a project, start with frame depth ranges, match them to glass stacks and wind loads, and layer in thermal break width to hit your energy targets. For façade planning, a quick curtain wall mullion sizes and frame depth map can save days of iteration.

T‑slot series

Common series: 20×20, 30×30, 40×40, 45×45, 60×60 are the workhorses.

Slot size: 6/8/10 mm families determine hardware compatibility.

Wall thickness: about 1.5–3.0 mm; heavier “high‑strength” variants exist for big spans and heavy equipment.

Standard length: ~6 m, cut‑to‑size per frame plan.

Frames and enclosures

Light benches: 20×20 or 30×30 with slot 6/8 mm.

Machine bases: 40×40 or 45×45 with slot 8/10 mm for stiffness and connector choice.

Heavy guards and shelves: 60×60 cores combined with 30×30/40×40 bracing.

Conveyors and shrouds

Open C‑channels and tubes: 30–120 mm envelopes, walls tuned to handling and span.

Panel carriers: angles and U/C channels in 20–60 mm widths; thin walls for weight savings.

If you need industrial aluminum profile dimensions that assemble fast and stay reconfigurable, standardize on one slot family across the plant. It simplifies your BOM, jigs, and spares. For quick planning, keep a t‑slot aluminum profile sizes 2020 3030 4040 4545 6060 cheat sheet on hand.

These shapes come from stock dies, which means faster lead times and predictable aluminum extrusion sizes. Typical bands:

Angles (equal/unequal): legs from 10–100+ mm; wall thickness 1.5–5.0 mm.

U/C channels: widths from 10–200 mm; legs/depth set by panel thickness and stiffness needs.

Square/rectangular tubes: 10×10 up to 200×200+ mm; walls 1.0–5.0 mm common.

Round tubes: diameters 10–200+ mm; walls 1.0–5.0 mm; thicker for handrails or structures.

Flats and bars: widths 10–150+ mm; thickness as needed for carriers and trims.

If your design allows it, using Aluminium Standard Profiles for carriers, covers, and non‑visible brackets is the fastest way to contain cost and lead time. Keep custom dies for critical, visible, or load‑bearing parts.

Green building zooms out from “what size fits” to “what size performs over decades.” Expect:

Deeper frames and mullions where triple glazing and wide air gaps improve U‑values.

Thermal break widths sized for climate and code; this influences overall frame depth.

PVDF on exposed façades to extend repaint cycles and preserve gloss.

Robust drainage paths and gasket allowances; these slightly affect envelope and wall needs.

The “right size” in Aluminium Green Building considers energy savings and maintenance. A few extra millimeters in frame depth paired with the right thermal break can raise comfort and lower lifetime operating cost.

Use case vs common size ranges

| Use case | Common W×H envelope | Typical wall | Standard length | Finish | Notes |

|---|---|---|---|---|---|

| Residential windows/doors | 50–120 mm frame depth | 1.2–2.0 mm | ~6 m | Anodized/Powder | Thermal break width drives depth |

| Commercial windows/doors | 70–150 mm frame depth | 1.5–2.5 mm | ~6 m | Powder/PVDF (exposed) | Hardware space and wind load matter |

| Curtain wall mullions | 50–250+ mm depth | 2.0–5.0 mm | ~6 m | PVDF | Depth set by wind, span, and deflection targets |

| T‑slot frames (light) | 20×20 / 30×30 | 1.5–2.0 mm | ~6 m | Anodized | Slot 6/8 mm accessories |

| T‑slot frames (heavy) | 40×40 / 45×45 / 60×60 | 2.0–3.0 mm | ~6 m | Anodized/Powder | Slot 8/10 mm; heavier connectors |

| Angles/U/C channels | 10–200 mm | 1.5–4.0 mm | ~6 m | Anodized/Powder | Stock dies; fast availability |

| Square/rectangular tubes | 10×10 to 200×200+ | 1.0–5.0 mm | ~6 m | Anodized/Powder | Stiffness driven by depth |

| Round tubes/handrails | Ø10–Ø200+ | 1.0–5.0 mm | ~6 m | Anodized/Powder | Consider grip diameter |

| Heat sink extrusions | 20–300 mm width | Fin‑dependent | ~6 m | Black anodized | Aluminium heat sink extrusion sizes vary by power density |

T‑slot mapping for quick selection

| Series | Slot size | Typical load level | Typical frame size | Accessories |

|---|---|---|---|---|

| 20×20 | 6 mm | Light stations, guards | Benches, light enclosures | Small panels, sensor mounts |

| 30×30 | 6/8 mm | Light–medium | Work tables, carts | Shelves, brackets |

| 40×40 | 8/10 mm | Medium | Machine bases, conveyors | Doors, polycarbonate panels |

| 45×45 | 8/10 mm | Medium–heavy | Enclosures, line frames | Hinges, heavy feet |

| 60×60 | 10 mm | Heavy | Large bases, gantries | Reinforced corners, casters |

If you need a formal aluminum extrusion sizes table for documentation, reuse the two tables above as your baseline and add columns for your project‑specific tolerances.

Wall thickness and stiffness

Wall thickness should follow loads and spans, not guesswork. A deeper shape with slightly thinner walls often beats a shallow, thick‑walled one on stiffness‑to‑weight. For example, in a mullion, increasing depth from 80 to 120 mm can allow a lighter wall while meeting deflection limits. In T‑slot frames, moving from 30×30 to 40×40 can reduce the number of braces without adding much weight. If you’re assembling an aluminium profile wall thickness chart, structure it by span and load, not just by “light/medium/heavy.”

Alloys and temper

Most Aluminium Profile projects use the 6xxx family because it extrudes cleanly and finishes well. Tempers like T5 and T6 cover a wide slice of building and industrial needs. Specialty alloys from 1xxx to 7xxx come into play for unusual strength, formability, or conductivity requirements, and can subtly affect wall thickness and achievable detail. The rule of thumb: tell your supplier the load, span, bend, and drilling needs, and let them recommend the alloy/temper that supports your target size.

Finishes and dimensional details

Anodized, powder coated, PVDF, and electrophoretic finishes don’t change the “size class,” but they do influence design details. Think drain/vent holes for consistent films, soft radiuses to avoid thin spots, and generous access for masking where needed. In tight T‑slot systems, ensure coating builds don’t interfere with slot hardware—a small allowance prevents assembly surprises. If you’re preparing an aluminium window profile size guide, include notes about gasket grooves, drainage paths, and thermal strip allowances; those are the real‑world dimensional details that speed installation.

When you ask “how big can an Aluminium Profile be?”, the answer depends on press capacity, die design, and handling. A mature producer with broad capacity unlocks bigger, cleaner designs:

Press fleet: more than 100 extrusion lines, including large‑tonnage presses such as 20,000T, 12,500T, 10,000T, 7,500T, 5,500T, 4,000T, and 2,500T. That range lets you run small trims and very large envelopes efficiently.

Maximum cross‑section: near 480 mm with the right die and process plan.

Single‑piece length: up to about 40 m when handling and quench strategy are arranged; ~6 m is the everyday shipping length.

Alloys and tempers: 1xxx–7xxx series and T1–T9 tempers available to match performance and finishing needs.

Finishing lines: anodizing, electrophoretic coating, powder coating, and PVDF aligned to AAMA 2605, Qualicoat, and GB5237.5.

QA backbone: direct‑reading spectrometers for alloy control, 12 aging furnaces for temper consistency, and accredited laboratories that keep dimensions and properties within spec at volume.

These capabilities matter because they keep your aluminum extrusion sizes feasible without last‑minute redesigns. They also underpin stable timelines for large façade packages, long T‑slot frames, and complex interior systems.

A clean RFQ removes guesswork and speeds sampling. Include:

A drawing of the cross‑section (STEP/DXF) with overall W×H, wall targets, and critical tolerances called out.

The end use: Construction Aluminium Profiles (windows, doors, curtain walls), Industrial Aluminium Profiles (T‑slot frames, conveyors, enclosures), Aluminium Standard Profiles (angles, channels, tubes), or thermal parts like heat sinks.

Standard length vs cut‑to‑size needs; share max piece length for elevators and site constraints.

Alloy/temper if you have a preference; otherwise state loads, spans, bending, and drilling plans.

Finish: anodized, powder, PVDF, or electrophoretic; note color/gloss targets if relevant.

Standards: AAMA, Qualicoat, and GB5237.5 if applicable.

Sampling plan: ask for a pilot run to confirm fit, finish, and assembly.

Q1: What is the standard length of an aluminum profile?

A1: The industry‑common standard length is around 6 meters because it balances shipping, handling, and cutting yield. Most suppliers cut to size for installation, so you can specify shorter lengths to fit elevators, rooms, or tight stairs. For special projects, single pieces can be extruded much longer with planned handling, but 6 m remains the most practical baseline for planning and aluminum extrusion sizes tables.

Q2: What is the most common aluminum profile?

A2: It depends on the industry. In factories, T‑slot families like 20×20, 30×30, 40×40, 45×45, and 60×60 dominate Industrial Aluminium Profiles. In buildings, window and door frames, sashes, and curtain wall mullions are the most common Construction Aluminium Profiles, with frame depths roughly 50–150 mm and mullion depths often 50–250+ mm. For brackets and carriers across sectors, Aluminium Standard Profiles—angles, channels, and tubes—are the everyday workhorses.

Q3: What are the sizes of aluminium sections?

A3: Everyday envelopes run from 10 to 200 mm with typical wall thickness around 1.0–5.0 mm. Window/door frames often sit at 50–150 mm frame depth; curtain wall mullions are commonly 50–250+ mm. T‑slot frames use series like 20×20 up to 60×60 with slot 6/8/10 mm. Large presses can make sections near 480 mm across. Most projects use ~6 m stock with cut‑to‑size lengths for site handling.

Q4: What are the common aluminum extrusion profiles?

A4: Common families include T‑slot structural beams in 20×20, 30×30, 40×40, 45×45, 60×60; window/door frames and sashes with thermal breaks; curtain wall mullions, transoms, pressure plates, and covers; Aluminium Standard Profiles such as angles, U/C channels, square/rectangular tubes, and round tubes; and purpose shapes like heat sinks with finned sections. Each family follows well‑known extruded aluminum sizes and aluminum extrusion sizes conventions for ease of selection.

Q5: How thick are aluminium profiles, typically?

A5: For general building and industrial uses, walls of about 1.0–5.0 mm cover most needs. Residential frames might be 1.2–2.0 mm, commercial frames 1.5–2.5 mm, and heavy T‑slot beams 2.0–3.0 mm. Heat sinks are special: fin thickness and spacing guide performance more than a single “wall” number. Always tie wall thickness to span and load rather than picking a number in isolation.

Q6: What’s the largest cross‑section and length you can make?

A6: With the right press and die, sections near 480 mm across are feasible. Single‑piece lengths can reach around 40 m with planned handling and quench strategy, though most orders ship at ~6 m for practicality. If you’re sizing a large façade blade or a deep mullion, share your target envelope early so die design and press selection keep your Aluminium Profile within capability.

Q7: Can profiles be cut to custom lengths and what tolerances apply?

A7: Yes. Cut‑to‑size is standard for stick systems and T‑slot frames. Tolerances tighten where parts mate—end faces for miter joints, slot interfaces, gasket grooves—while general faces can stay at standard. When you prepare a drawing, call out critical dimensions and acceptable general tolerances; it speeds quoting and prevents over‑engineering. If you need an aluminium profile standard length 6m cut to size plan, share site constraints and packing preferences upfront.

Sizing an Aluminium Profile comes down to a few clear ideas: cross‑section envelope, wall thickness tuned to loads and spans, and practical stock lengths around 6 m with routine cut‑to‑size. Industrial systems lean on recognizable T‑slot series like 20×20 through 60×60; building systems talk frame depth and mullion depth, shaped by glazing and wind. If you keep those anchors in mind, you can move from a sketch to a confident specification quickly, avoid overbuilding, and preserve flexibility for installation. When you’re ready to turn ranges into real parts, visit the aluminium profiles catalog on the products page (https://www.fenglualu.com/products.html), browse construction aluminium profiles, industrial aluminum profiles, aluminium standard profiles, and aluminium heat sinks, and request a sample based on your drawing and environment. That simple next step turns “what size are aluminium profiles?” into a clean bill of materials you can order and install.